Home // BioFabUSA

BioFabUSA: Advancing the Future of Regenerative Manufacturing

BioFabUSA, a program of ARMI, is a public-private partnership with over 170 member organizations from industry, academia, government, and nonprofits. The program brings together science, engineering, and advanced manufacturing to enable the reliable, scalable, and secure production of regenerative medicine technologies.

BioFabUSA focuses on developing the standards, tools, and workforce needed to transition tissue and cell-based innovations from research to commercial-scale manufacturing—supporting U.S. leadership in biotechnology and strengthening domestic manufacturing capabilities in a field vital to health, economic, and national security.

BioFabUSA is focused on enabling the scalable, secure, and cost-effective manufacturing of cells, tissues, and organs—advancing technologies critical to national health, readiness, and innovation.

By integrating science, engineering, and manufacturing, BioFabUSA supports the development of standards, platforms, and workforce programs that strengthen U.S. leadership in regenerative medicine.

This work helps address priority health challenges, support medical readiness, and create opportunities for high-quality job growth in advanced biomanufacturing.

Vision

To secure U.S. leadership in biotechnology and advanced biomanufacturing by building the infrastructure, standards, and workforce needed to produce regenerative medical technologies at scale—and at the point of need.

BioFabUSA envisions a future where the United States leads in the development and deployment of cell, tissue, and organ-based therapies that strengthen national health, economic security, and military readiness.

Timeline: How BioFabUSA Came to Be

The United States Department of Defense (DoD) has long understood the need for regenerative technology to maintain its warfighters’ readiness and to restore form, fit, and function to our nation’s warfighters and veterans. What was needed was a way of manufacturing that technology, at scale, to get it to the people that need it.

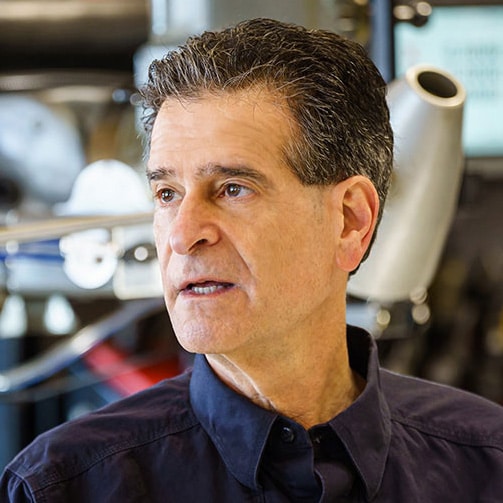

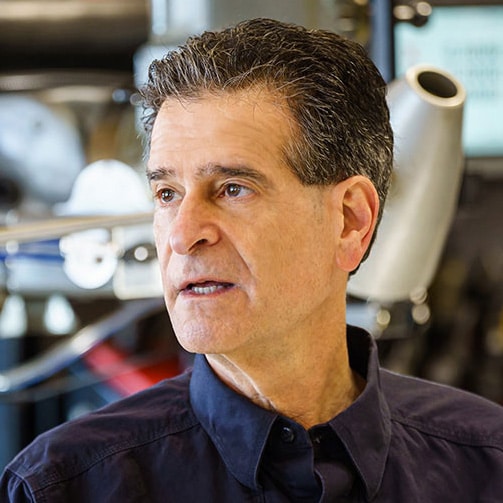

Dean Kamen

Dean Kamen—the serial inventor with an inimitable history of turning unconventional ideas into commercial successes—could see the potential for a new frontier in the way we care for people: He had a vision of making the world a better place through education—and experience forging highly successful public-private partnerships, such as FIRST (For Inspiration and Recognition of Science and Technology), to do so. So, he quickly rallied at team to write what became the new institute’s winning proposal.

Tom Bollenbach, Maureen Toohey and Jim Scott.

The proposal’s authors—who would later become the Chief Technology Officer, the Deputy Executive Director and the Chief Operating Officer, respectively, of the Advanced Regenerative Manufacturing Institute (ARMI): Tom Bollenbach, Maureen Toohey and Jim Scott.

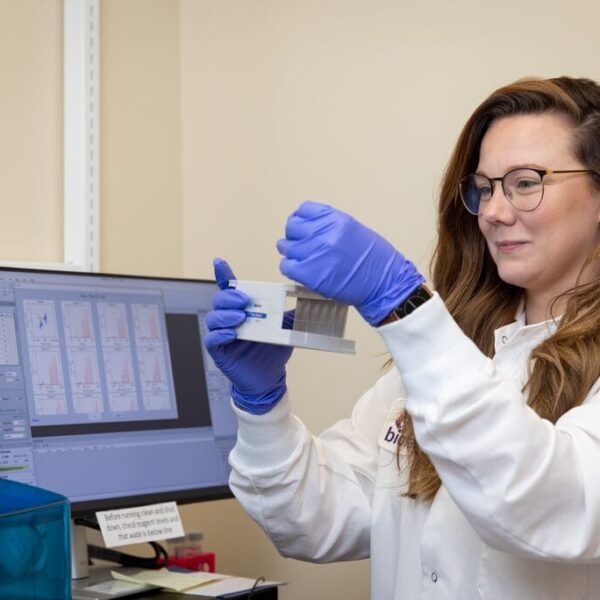

Dr. Richard McFarland

Understanding that manufacturing is the bridge between a scientific project and a commercial product and that regulatory expertise is a key part of this process, the team added a new member in Dr. Richard McFarland. Dr. McFarland, a pathologist, brings to his Chief Regulatory Officer role 17 years of experience inside the U.S. Food and Drug Administration.

Rockwell Automation CEO Blake Moret

Timeline: How BioFabUSA Came to Be

The United States Department of Defense (DoD) has long understood the need for regenerative technology to maintain its warfighters’ readiness and to restore form, fit, and function to our nation’s warfighters and veterans. What was needed was a way of manufacturing that technology, at scale, to get it to the people that need it.

2016

In 2016, the government called for proposals to launch the Manufacturing USA innovation institute focused on the biofabrication of tissue.

Dean Kamen—the serial inventor with an inimitable history of turning unconventional ideas into commercial successes—could see the potential for a new frontier in the way we care for people: He had a vision of making the world a better place through education—and experience forging highly successful public-private partnerships, such as FIRST (For Inspiration and Recognition of Science and Technology), to do so. So, he quickly rallied a team to write what became the new institute’s winning proposal.

The proposal’s authors—who would later become the Chief Technology Officer, the Deputy Executive Director and the Chief Operating Officer, respectively, of the Advanced Regenerative Manufacturing Institute (ARMI): Tom Bollenbach, Maureen Toohey and Jim Scott.

Alongside Dean Kamen, together they established BioFabUSA, a program of ARMI, as an entrepreneurial organization that would apply engineering and manufacturing expertise to the world of biology. Bringing biologists and physicians and manufacturing engineers to the same table and getting them to work together, they wagered, would serve not only the nation’s warfighters but also people who need replacement organs and people who need highly skilled jobs.

Understanding that manufacturing is the bridge between a scientific project and a commercial product and that regulatory expertise is a key part of this process, the team added a new member in Dr. Richard McFarland. Dr. McFarland, a pathologist, brings to his Chief Regulatory Officer role 17 years of experience inside the U.S. Food and Drug Administration.

May 2017

Rockwell Automation CEO

Blake Moret

Kamen brought together industry partners, academia, and others he had worked with over the years to form a board of directors for ARMI unlike any other non-profit.

July 2017

ARMI launched BioFabUSA in July 2017, with an $80 million DoD grant. The program now has more than 170 member organizations from industry, academia and the nonprofit sector.

170+ Members

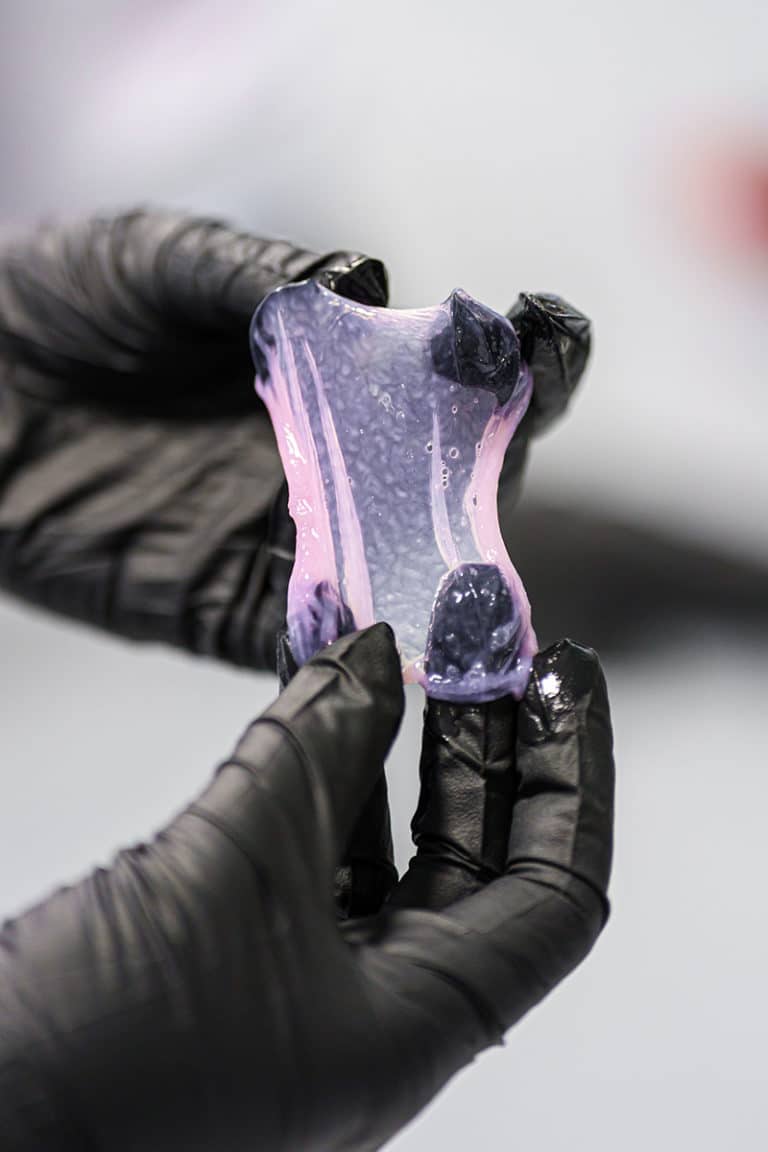

What is BioFabrication?

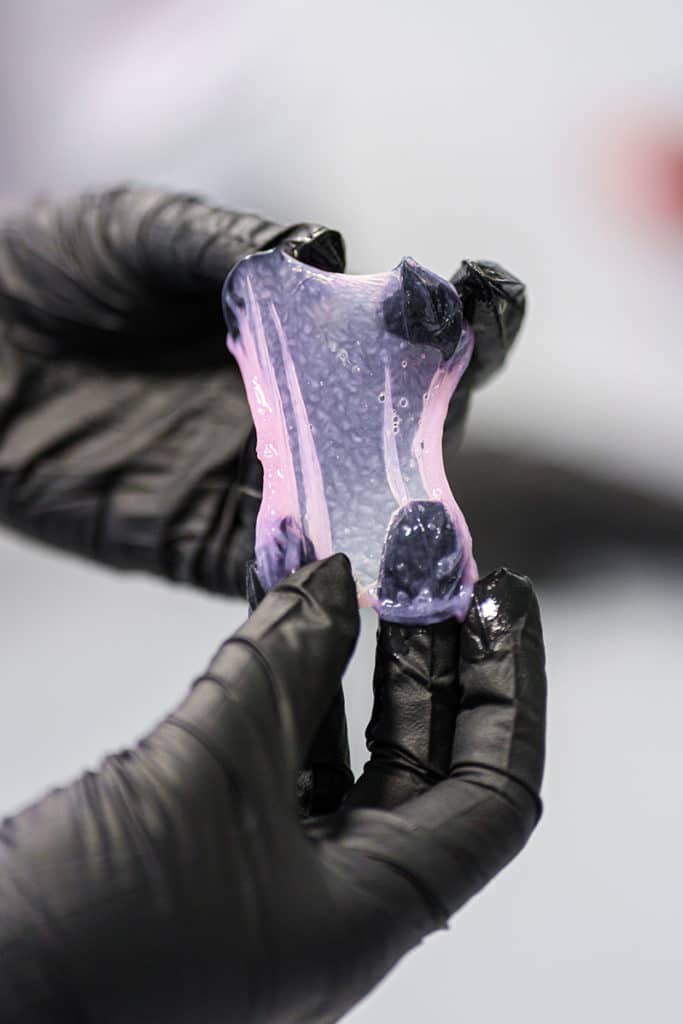

Biofabrication is the fabrication of complex biological systems from raw materials, including living cells and matrices/scaffolds, to form functional cells, tissues and organs.

“What makes cells so great is what makes them difficult to manufacture, which is that they’re so variable.”

ARMI CTO Tom Bollenbach