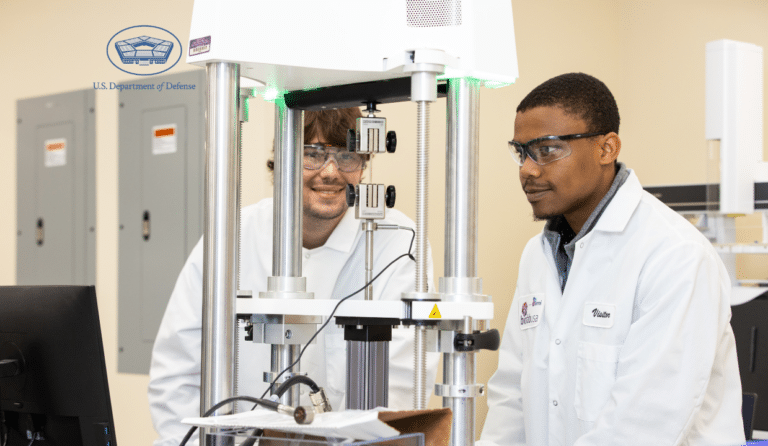

“We believe non-destructive mechanisms of monitoring tissue engineering research constructs has a lot of room for evolution,” said Sathya Janardhanan, of Apsis Healthcare Systems. He continued by saying, “In the biologics industry, we are working on prototypes that serve to detect multiple parameters of protein intermediates and raw materials, using components and technology we have sourced from the industry.”

Apsis Healthcare Systems founded in 2019 and based at Gaithersburg, MD is a Process Analytical Technology organization that brings together a suite of technology aimed at advancing the state of manufacturing in the biologics, cell therapy and regenerative medicine industries. Apsis hopes to achieve this advancement in manufacturing with three main product development programs, namely novel detection technologies, specialized manufacturing hardware design and Process Data Lakes bringing advances in Cloud computing, Data Visualisation and Process Modeling to the Bioprocess Industry.

“We intend to do the heavy lifting in the area of new detection technologies, using our composite instrumentation platform – Curie and integrating said simplified PAT with the manufacturing process equipment in the tissue engineering and regenerative medicine space,” said Janardhanan, who along with the Apsis Healthcare’s team collectively bring decades of Process Engineering experience to this emerging space.

As a tools & technologies company, Apsis Healthcare Systems is thrilled to have formally joined the ARMI | BioFabUSA community and attempt to aid the regenerative medicine industry by developing automated cGMP-equipment that can support both R&D as well as commercial & clinical manufacturing. The goal is to provide the industry with a broader toolset, with which cell-based processes can be controlled and to provide access to targeted hardware and software that can be adapted to the unique needs of each regenerative medicine research group.

Apsis Healthcare Systems views their partnership with ARMI | BioFabUSA as an opportunity to discover new applications for their novel detection hardware, smart processing skids, and process monitoring software. “Being a new start-up in the area of PAT, we see that being a part of BioFabUSA would give us an opportunity to enhance our availability to regenerative medicine process scientists, who can benefit from rationally developed PAT”, added Janardhanan.

Apsis is also developing a modular manufacturing automation system, Ozy, which is designed to be cGMP-ready and enable scientists to carry out process development and early clinical manufacturing in a single platform, with or without the use of Process Analytical Technology. This manufacturing platform, Ozy is being designed to synchronize effectively with Apsis Healthcare’s own PAT platform Curie and other such commercially available PAT modules.

Apsis Healthcare Systems is looking forward to new alliances with ARMI based projects and the expand their service, ranging from PAT to cGMP consulting to other members here in the tissue engineering community.

“We strongly believe that our cGMP-centric approach to product development will help early stage companies seamlessly bridge the gap between research-use and cGMP-use by providing a single platform that can be utilized during development, engineering-runs and cGMP production,” concluded Janardhanan.